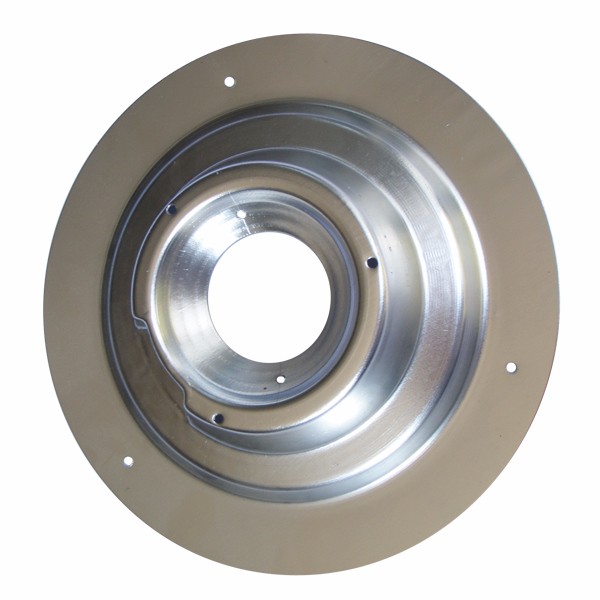

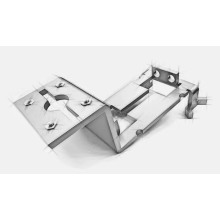

OEM small part stainless steel garage door part metal precision metal stamping parts

Basic Info

Model No.: Custom Made(stamping parts)

Product Description

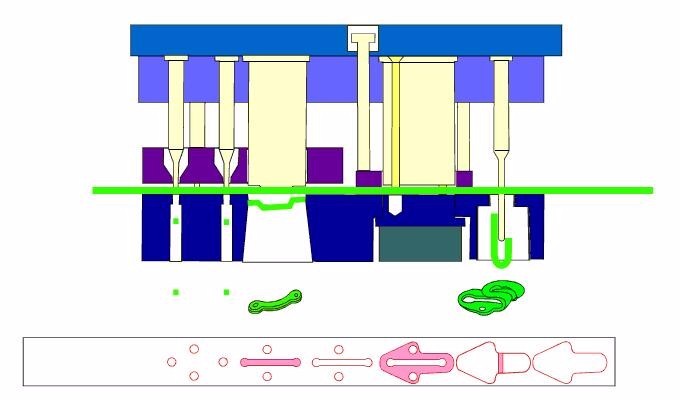

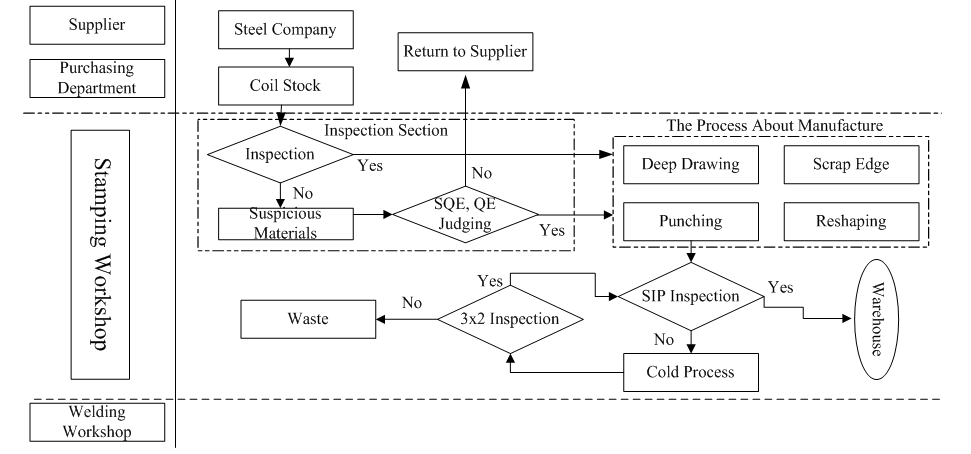

Stamping Technology processing:

Stamping mainly by technology classification, separation process can be divided into two categories and the forming process. Separation step, also known as punching, stamping its purpose is to separate from the sheet along a certain contour, while maintaining the quality requirements of separation sections (Table 1). The purpose is to make the forming process of sheet plastic deformation without breaking the blank condition, shape and size of the workpiece into the desired. In actual production, it is often used in a variety of processes integrated workpiece. Punching, bending, shearing, stretching, bulging, spinning, correction of several major stamping process.

Stamping sheet metal surfaces and the inherent properties:

For stamping materials are requested-

① precise thickness uniformity.

② surface clean, no spots, no scars, no bruises, no surface cracks.

③ yield strength uniformity, no obvious direction.

④ uniform elongation.

⑤ low yield ratio. Yield limit and ultimate strength of the material than is called the yield ratio. Low yield ratio can not only reduce the deformation resistance, but also reduce the tendency of drawing wrinkled, reducing the amount of spring back after bending, bending member to improve accuracy.

⑥ hardening low.

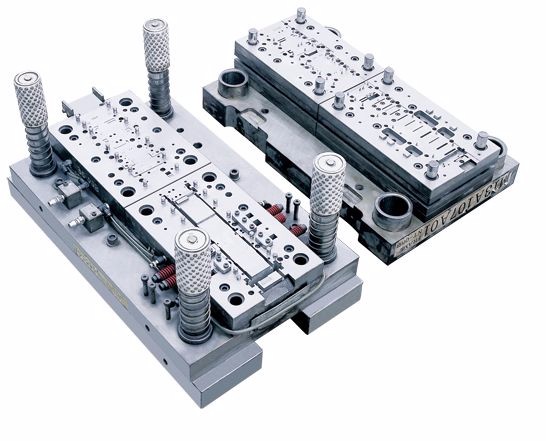

Stamping Tooling

Stamping die, is in the cold stamping process, the material (metal or non-metallic) processed into parts (or semi-finished products) of a special process equipment, known as cold stamping die (commonly known as cold die). Stamping is a method of applying pressure to a material at room temperature by means of a mold mounted on a press to produce separate or plastic deformation to obtain a desired pressure machining method for the desired part. Manufacture of stamping die materials are steel, carbide, steel cement, zinc alloy, low melting point alloy, aluminum bronze, polymer materials, etc.

Packing Details : Packing, solid bicycle saddle, 50pcs/carton

Delivery Details : 3-30 days after order of Solid bicycle tire tubes

1. Why we put orders to you, tell me your advantage?

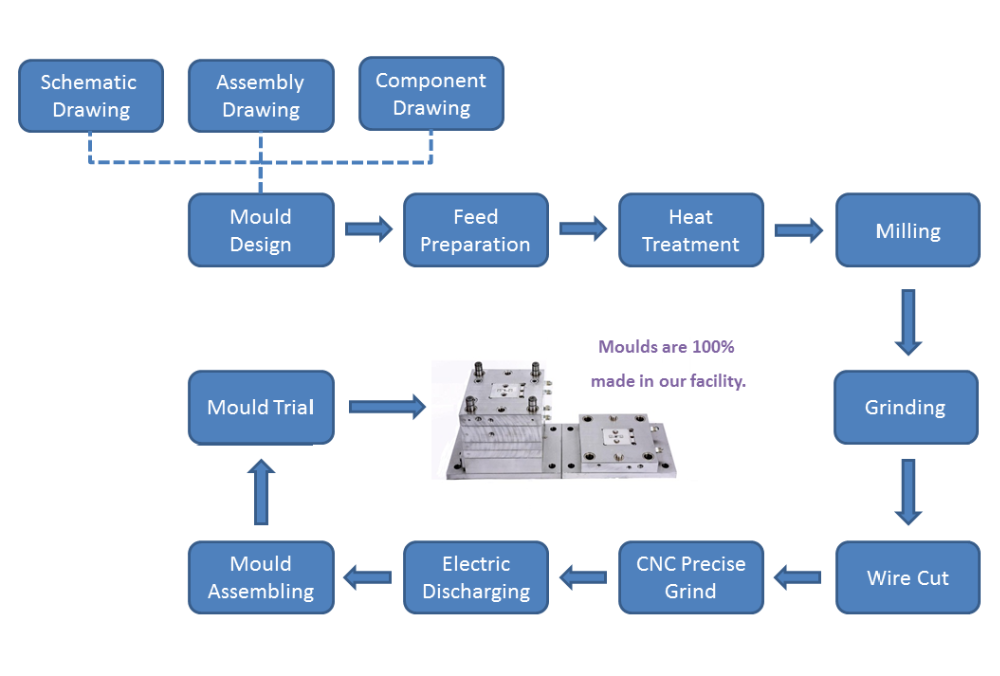

We are a professional manufacturer with our own mould workshop, our own RD,QC,PD professional team,can do ODM and OEM parts, support you modify products design, competitive price, short lead time.

2. If we don’t have drawing, can you make drawing for me?

Yes, we make the drawing of your sample and duplicate the sample.

3. When can I get the sample?

Sample: 30-45 days after you start to make mold. The accurate time depends on your product.

4. What is your main order time?

Order time: 20-30 days after the payment. The accurate time depends on your product.

5. What is your payment method?

Tooling: 50% deposit, balance 50%

Main order: 40% deposit, balance 60% to be paid before shipment.

6. Which kind of file format you can read?

PDF, ISGS, DWG, STEP, MAX..

7. If you export to our country before, can I get the information of your import customer in our country?

We can’t offer you all the information of our customer because we have duty to protect our customers’ privacy. But we can provide you some part of B/L.

Product Categories : CNC HARDWARE > Other CNC HARDWARE

Premium Related Products