Pressure Die Casting OEM Machine Parts/Aluminum Die Casting Part for communication equipment enclose

Basic Info

Model No.: Precision Casting

Product Description

Pressure Die Casting OEM Machine Parts/Aluminum Die Casting Part for communication equipment enclose

High pressure die casting

In the high pressure die casting process the metal is forced into a high grade steel tool at high speed and -pressure. The casting temperature is roughly 700°C during casting. The use of vacuum casting technology is an advantage in order to achieve superior quality for light and thin walled components.

High pressure die casting is a competitive casting method when components have requirements which cannot be achieved by other casting processes such as:

High volumes

Better tolerances

Smooth surface finish Send inquiry>>>>

Since established in 1997, Longsheng has introduced 22 technical talents with rich die casting experience. Among them 8 employees work for the mould design department, 12 employees work for the mould manufacturing departments, and 2 chief engineers.

We set our own mould workshop, and introduce two 1650t die casting machines and injection moulding machines to establish the injection mould workshop in 2016, with an estimated investment of RMB 25 million.

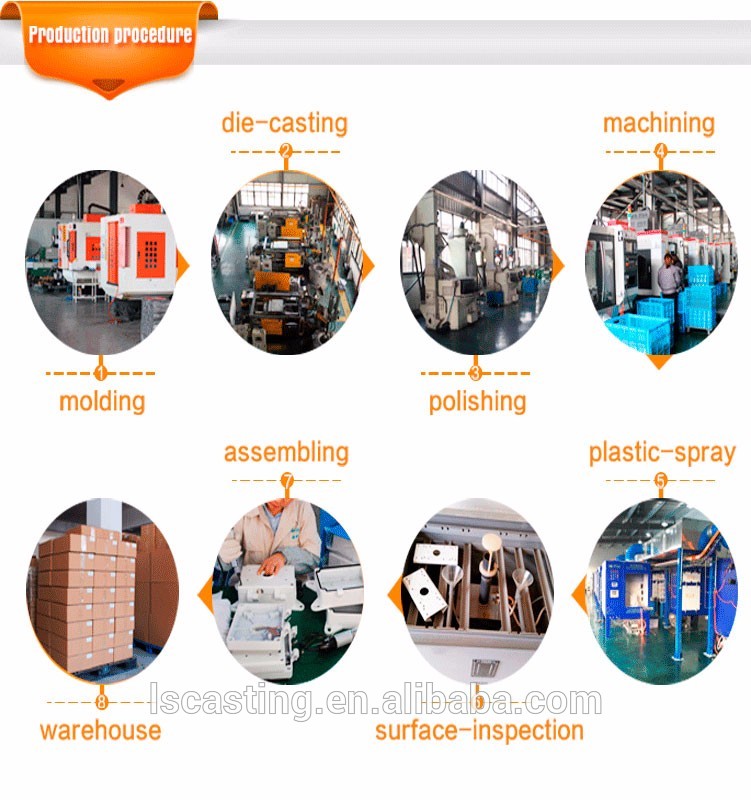

Mould workshop

Professional mould design team. The mould workshop has been oriented to the company production demands and production requirement has set up a complete mould development & peration process and mould maintenance & alloction process.

Large die casting workshop

Over 20 years professional die casting experience, we owns 18 sets Tizumi die casting machines including two 180t machines, six 300t machines, six 400t machines, one 800t machine, two 1250T machines and one 1650T machine.

Machining workshop

We have 45 sets Winner CNC maching centers and about 20 auxiliary maching devices, such as CNC machines, milling machines, wire cutting machines and driling machines, 1 vertical machining center. There are over 100 relevant personnel.

Spraying workshop(Patent)

Apply surface treatment & plastic spraying and electrostatic adsorption process, design reasonable & automatic spraying system, select the appropriate moulding powder and ensure good operating environmental conditions to complete the spraying procedure for products, protect products from corrosion lengthen the service life and make products more beautiful.

Assembly & packaging workshop

We pack our goods in standard cartons. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

We divide the space based on the different function areas. Weekly workshop cleaning and daily worktable cleaning are carried out by cleaner. Arrangement and record regularly and records ensure the stable production and operation effctively.

Storage

We have a large warehouse divided by the principle of the commodity performance and consistent maintenance measures.

1. Why we put orders to you, tell me your advantage?

We are a professional manufacturer with our own mould workshop, our own RD,QC,PD professional team,can do ODM and OEM parts, support you modify products design, competitive price, short lead time.

2. If we don’t have drawing, can you make drawing for me?

Yes, we make the drawing of your sample and duplicate the sample.

3. When can I get the sample?

Sample: 30-45 days after you start to make mold. The accurate time depends on your product.

4. What is your main order time?

Order time: 20-30 days after the payment. The accurate time depends on your product.

5. What is your payment method?

Tooling: 50% deposit, balance 50%

Main order: 40% deposit, balance 60% to be paid before shipment.

6. Which kind of file format you can read?

PDF, ISGS, DWG, STEP, MAX..

7. If you export to our country before, can I get the information of your import customer in our country?

We can’t offer you all the information of our customer because we have duty to protect our customers’ privacy. But we can provide you some part of B/L.

Joyce sales Manager

Hangzhou LongSheng Industry & Trade Co., Ltd

Add: No. 18-3, Houshan Road, Yuhang District, Hangzhou, ZheJiang, China

Tel: +86 (0)571 88731337 Fax: +86 (0)571 88730882

Skype: zhiqun Huang

Mobile No: +8615868837462

Product Categories : ALUMINIUM DIE CASTING > AUTOMOTIVE/MOTORCYCLE DIE CASTING

Premium Related Products